Long Shaft High Pressure Sealless Submerged Magntic Pump

Brand DALIAN KEHUAN PUMP

Product origin DALIAN,LIAONING,CHINA

Delivery time THREE MONTHS

Supply capacity SUFFICIENT SUPPLY

Kehuan pump make a comprehensive breakthrough in the status quo of magnetic pumps (such as High power, High temperature, Mud, Easy vaporization, High melting point, etc.)

Design framework: We use European advanced hydraulic model;

Design standards according to American petroleum institute standard API685.

High standard material application: Permanent magnet (Sm2Co17, Temp. -196~450℃), Sliding bearing (SSIC), Containment shell(HC-276), Rolling bearing (SKF/NSK), Coupling (Wuxi Chuang ming) /German KTR), Electric motor (Nan yang/Jiamusi).

Long Shaft High Pressure Sealless Submerged Magntic Pump

Product attributes:

Maximum head :>150m

Maximum fiow:>400L/min

Driving type:Motor

Working Pressure:Middle Pressure Pump

Working impeller number:Single or Multistage

Working impeller inlet way:Single Suction Pump

Pump shaft positon:Horizontal Pump

Impeller structure:Closed

Transportation package:Wooden Case

Specification:API 610 standard

Trademark:Dalian Kehuan Pump Co.,Ltd

Origin:Dalian,Liaoning,China

Size: DN40~400

Flow:~400m3/H

Head:~200m

Temperature: -20~300 Degrees Celsius

Pressure:~5MPa

Application:

KY model pumps are of vertical,single stage and single suction, long shaft submerged pumps, available for all kinds of sewage conveying from power plants,

chemical factories and wastewater traetment plants.

Thermal power factory

chemical factory

wastewater treatment factory

steels factor,steels rolling mill

paper mill

cement factory

Capacity Q 2-400m3/h

Head H 5-100m

Working temperature T -20~ +200°C

Structural:

Safe and reliable connecting shaft structure.

Adopt multi-points support for the rotor component and pumps runs safely and reliably.

Adopt external or self-lubrication for sliding bearing.

The impeller has submerged into medium when the pump begins to run,so start up become easy without air evacuation.

Adopt two-runner casings(the diameter is graeter than 80mm).It is small of radial force of rotors component, of shafts deflection and of wear and tear

from sliding bearings,so long service life.

The pump runs clockwise looking from the motor end.

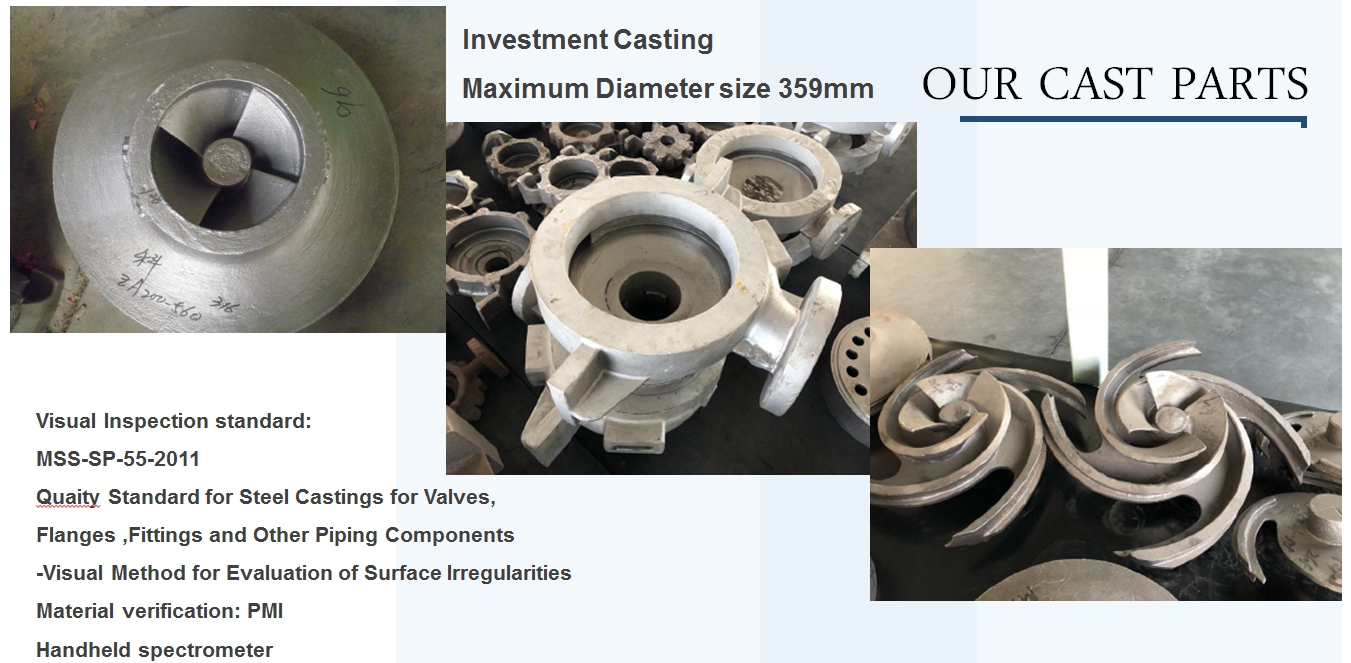

Material:

Carbonsteel; chromed steel; austeniticstainlesssteel; duplexsteel; Titanium and Titanium Alloys; Hastelloy C-276 and other special materials;

* It depends the customer's request.

| S-5 | S-6 | C-6 | S-8 | A-7 | A-8 | D-1 | D-2 | |

| Casing | Cast steel | Cast steel | CA15/CA6NM | Cast steel | AUST SS | 316 AUS | DUPLEX | SUPER DUPLEX |

| Impeller | Cast steel | 12%CR | CA15/CA6NM | 316 AUS | AUST SS | 316 AUS | DUPLEX | SUPER DUPLEX |

| Shaft | AISI4140 | AISI4140 | SS420 | 316N | AUST SS | 316N | 2205 | 2507 |

| Wear rings | 12%CR | 12%CR | 12%CR | 316 Hard faced | AUST SSHard faced | 316 Hard faced | Duplex Hard faced | SUPER Duplex Hard faced |

| Bearing Frame | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel |