API610 BB1 Axially Split Double Sution Centrifugal Pump

Brand DALIAN KEHUAN PUMP

Product origin Dalian,Liaoning,China

Delivery time THREE MONTHS

Supply capacity Sufficient supply

Kehuan pump make a comprehensive breakthrough in the status quo of magnetic pumps (such as High power, High temperature, Mud, Easy vaporization, High melting point, etc.)

Design framework: We use European advanced hydraulic model;

Design standards according to American petroleum institute standard API685.

High standard material application: Permanent magnet (Sm2Co17, Temp. -196~450℃), Sliding bearing (SSIC), Containment shell(HC-276), Rolling bearing (SKF/NSK), Coupling (Wuxi Chuang ming) /German KTR), Electric motor (Nan yang/Jiamusi).

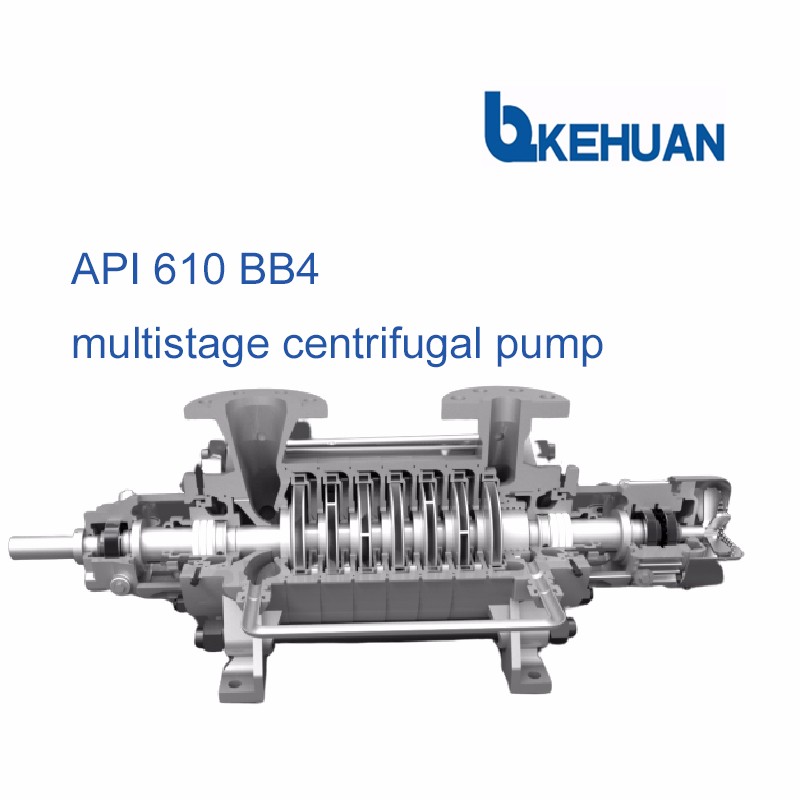

API610 BB1 Axially Split Double Sution Centrifugal Pump

Product attributes:

Maximum head :>150m

Maximum fiow:>400L/min

Driving type:Motor

Working impeller number:Muitistage Pump

Working impeller inlet way:Single Suction Pump

Pump shaft positon:Horizontal Pump

Installation height:Suction Centrifugal

Impeller structure:Closed

Transportation package:Wooden Case

Specification:API 610 standard

Trademark:Dalian Kehuan Pump Co.,Ltd

Origin:Dalian,Liaoning,China

Size: DN800

Capacities: ~ 10000m3/h

Heads: ~ 200m

Temperature : ~ 160ºC

Pressures: ~ 50 bar

Design:

TheBB1 series is single stage ,double suction,axial split,volute casing pumps

Suitable for pumping clean or slightly polluted liquids. Apply in the industries of water feeding and water treatment ,irrigation and sewage treatment,power station ,zone heat supply ,pulp and paper ,pipeline and offshore platform.

Oil Lubrication, Where oil lubricated bearings are fitted the oil rings function equally well irrespective of the direction of ritation so reverse running is not detrimental to the securty of the unit.

The oil rings rotate with the shaft and contiuously deliver oil into the bearing cap whence it flows back through the bearing into the oil reservoir.

The combination of generous bearing dimensions and dependable lubrication assists the SM series of pumps in achieving a long. trouble free service life.

Seedy inspection and dismantling of the complete rotating element is assured by the axially split casing design.

Cast steel , LTCS

Chrome steel CA15/CA6NM

Austenitic Stainless steel

Duplex steel

Super Duplex steel

Hastelloy

Titanium C2, C3

Titanium alloy C5,C12

904L

Alloy 20

*It depends the customer's request.

| S-5 | S-6 | C-6 | S-8 | A-7 | A-8 | D-1 | D-2 | |

| Casing | Cast steel | Cast steel | CA15/CA6NM | Cast steel | AUST SS | 316 AUS | DUPLEX | SUPER DUPLEX |

| Impeller | Cast steel | 12%CR | CA15/CA6NM | 316 AUS | AUST SS | 316 AUS | DUPLEX | SUPER DUPLEX |

| Shaft | AISI4140 | AISI4140 | SS420 | 316N | AUST SS | 316N | 2205 | 2507 |

| Wear rings | 12%CR | 12%CR | 12%CR | 316 Hard faced | AUST SSHard faced | 316 Hard faced | Duplex Hard faced | SUPER Duplex Hard faced |

| Bearing Frame | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel | Cast steel |