Dye penetration control

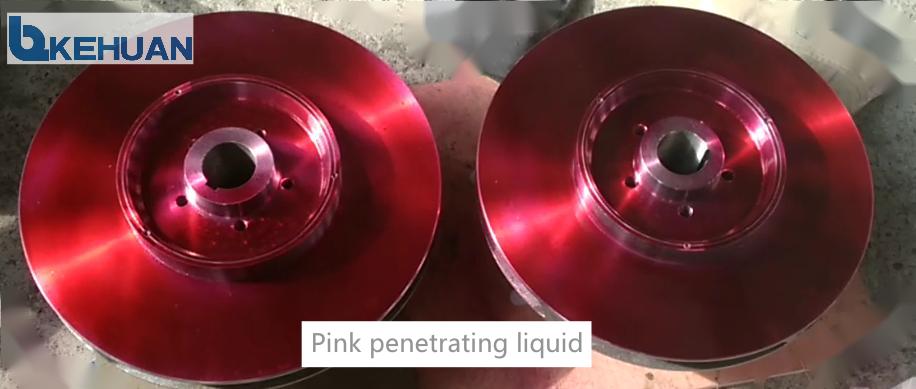

At the customer's request, a dye penetrant inspection can be performed on magnetic pump casing or impeller. Surface cracks in particular represent dangerous defects in workpieces that are exposed to high loads. The dye penetrant inspection method is recommended for detecting precisely such surface cracks, for example on weld seams. The workpiece surface to be inspected is first carefully cleaned. Then a strongly penetrating liquid is applied over a large area of the surface to be tested and remains there for a defined period of time. The workpiece is then cleaned again and a developer liquid is applied, again for a defined time. After this developer is rinsed off, defects such as cracks or pores become visible under light. However, this test only makes surface defects visible at a shallow depth of up to something like 3mm.

In addition, the gas leak test helps to detect leaks in the pump.